Automatic Filling Equipment

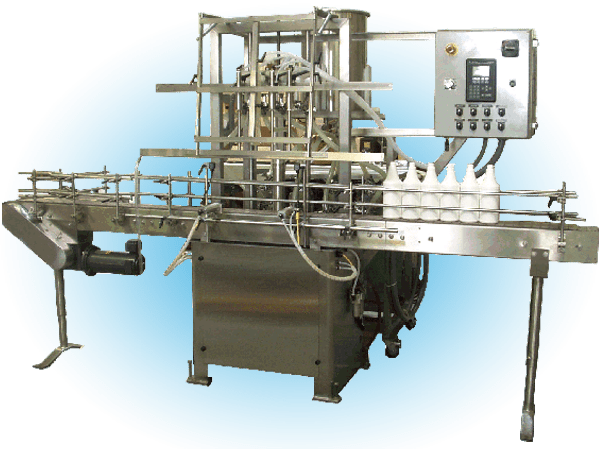

Fully Automatic Inline Filler

This machine is engineered to have the flexibility of filling containers as small as 2 oz and as large as 2 1/2 gal (F-Style) at rates as high as 80 containers per minute. Standard Features include a product pump, reservoir, pressure manifold, AB photo sensors and a variable speed on-board 10 foot conveyor and drive system. Also variety of different style filling nozzles for those hard to fill foamy & viscous products. Automatic In-Gate and Out-Gate cylinders control container flow into and out of the filling station. The SLA’s ease of operation provides a minimum change over time and years of trouble free service.

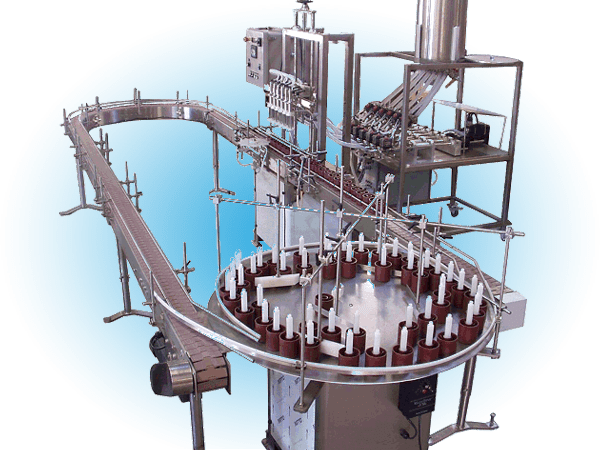

Rotary Gear/Lobe Pump Filler

The Packaging Dynamics, Ltd. , Inline Rotary Pump Liquid Filler model SLA-RL was designed to deliver an accurate means for filling thin to very viscous products without overflowing or volume limitations. An individual servo motor coupled with a Gear or Lobe pump is mounted behind the machine frame and supplies product to each individual filling head. This allows for a large variety of container types to be filled, from 2 oz. to 5 gallon pails. Automatic Indexing allows bottles to enter and exit the fill area smoothly. An Allen Bradley PLC controlled and Panel View operator interface controls the independent nozzle pulse settings. Each filling head can be turned on or off and individually adjusted. With stainless steel construction, sanitary connections, Allen Bradley nema 4 electric’s, quick change nozzle handles and variable speed conveyor; the SLA-RL provides easy change over and cleanup between product runs.

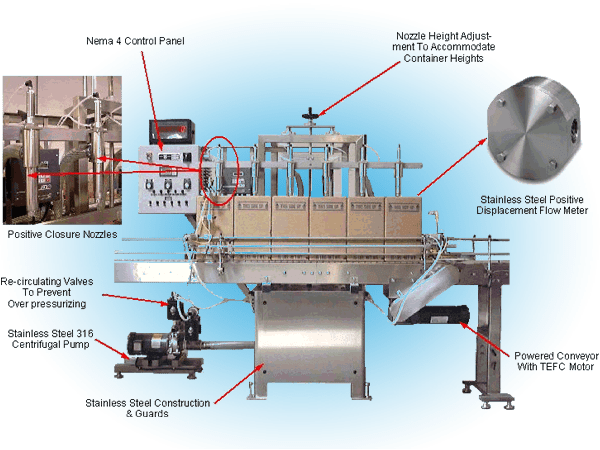

Positive Displacement Filler

Packaging Dynamics Ltd. introduces the Accu-Flo Liquid Filler which utilizes positive-displacement flow meter technology. Our Positive Displacement Flow Meters use two rotating thermoplastic impellers driven by flowing liquid. Magnets imbedded in the impellers activate a non intrusive sensor which generates a pulsed output signal. Each pulse represents a known volume. This process allows our fillers to achieve a +/- 0. 5% accuracy and repeatability. The meter has only two moving parts, no bearings, no motors, no clutch or brakes and is programmed through our microprocessor touch pad for virtually any volume. This reduces the amount of mechanical moving parts and ads to the long term reliability of the system. The Flow Meter sizes range from 1/4″ NPT to 1. 5″ NPT depending on the size of the container, the viscosity of the product and the speed required. This equipment is available from single to twelve heads and handles viscosities from water thin to gels and thick creams. Available in semi- and fully-automatic variations, the Accu-Flo can be used to fill from fractional containers to 5 gallon pails and 55 gallon drums offline.

Servo Driven Straight Line Piston Fillers

The Packaging Dynamics, Ltd. Automatic Straight-Line Servo Controlled Piston Filling Machine Model SLA-RVP has been engineered to fill thin to heavy viscosities to creams & thicker lotions into containers as small as 1/4 oz and as large as 1 gal at rates as high as 100 containers per minute depending on container size and product consistency. Accuracy and repeatability are within +/- 0. 3 %. Standard equipment includes Allen Bradley (AB) PLC controls, product reservoir, variable speed 10 foot conveyor, (AB) photo-optic sensors, In-Gate and Out-Gate cylinders (or star wheel) for controlling container flow and a “user-friendly” (AB) Panel View Operator Interface. Quick nozzle alignment and conveyor rail adjustment handles provide for a quick and easy change over.